Space

Top space companies and agencies, including ESA, choose us as their subsystem provider, integrators and preferred partner.

We design, build and assemble space systems, which perform nominally on their first flight. Rooted in the best traditions of the space industry worldwide and with a strong background in complex electronics design, we are about to make the next leap in satellite design and development with our dedicated Hypersat microsatellite platform.

Space Heritage

Using subsystems and processes with proven flight heritage is key when mitigating risks related to the development of new satellite systems. At Creotech Instruments, we have extensive experience in designing, manufacturing, testing and assembling flight models of spacecraft subsystems for a variety of clients, including the European Space Agency and various commercial partners. Read on for highlights below.

Fourteen successful space missions (and counting..)

Creotech Instruments contributed to a wide selection of successful space missions. This includes commercial and research satellites in Low Earth Orbit (e.g. ICEYE-X2, OPS-SAT), scientific payloads aboard the International Space Station (ASIM, DESSIS) and a Martian orbiter (ExoMars Trace Gas Orbiter). All without a single failure on our part. We are committed to maintaining this track record in the upcoming missions.

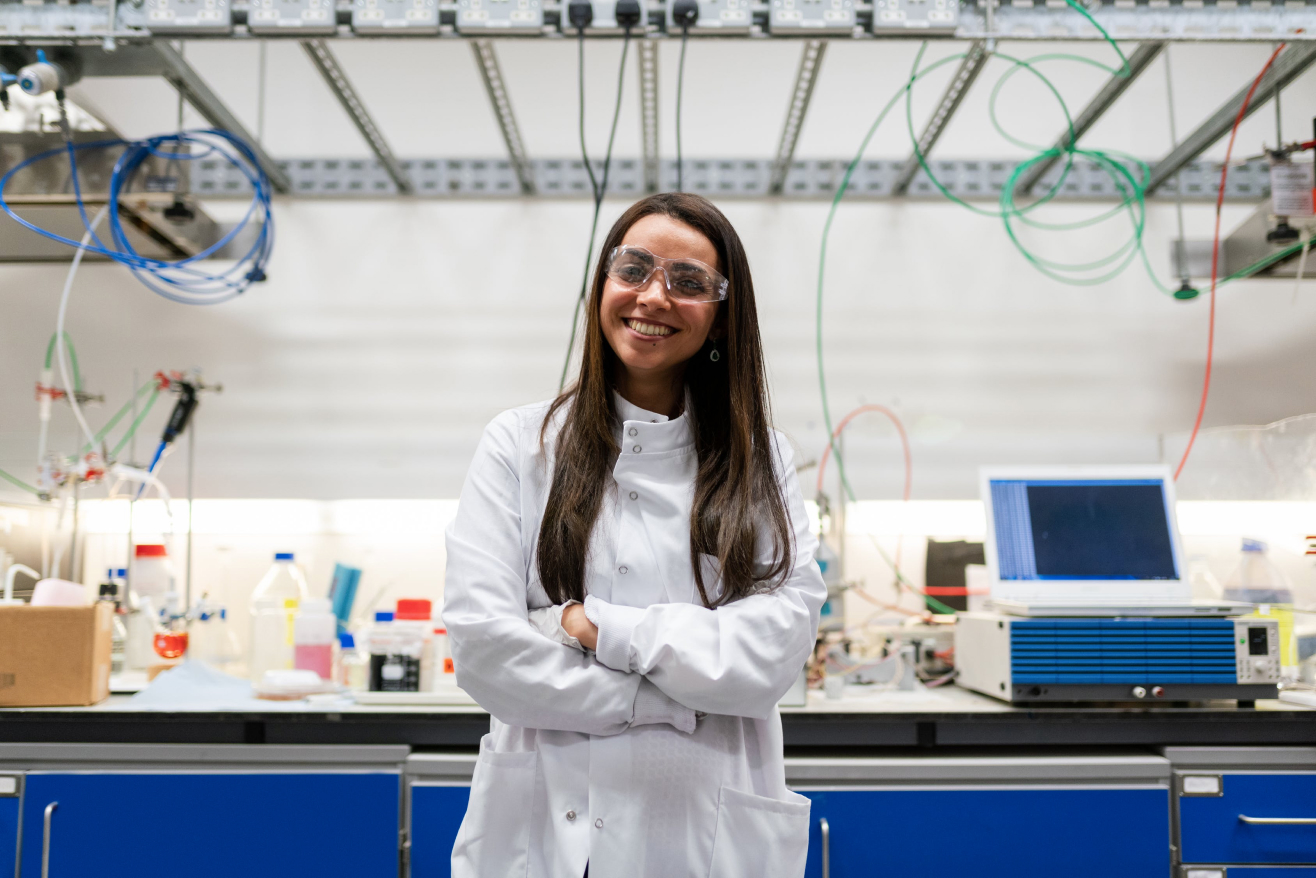

Team of experienced scientists and engineers

Our dedicated satellite projects team consists of over 30 specialists, including several former NASA, ESA and POLSA employees. This team is supported by a strong research & development team, including 40 additional engineers with an extensive background in complex electronics. Aiming to have a comprehensive understanding of spacecraft as a whole, our team is capable of designing, integrating and testing components for all subsystems found in a typical satellite bus.

Industry’s best practices and highest standards

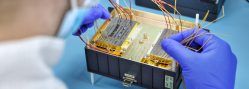

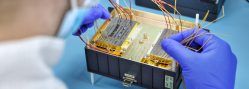

As the adage goes, space is hard. To avoid repeating the same mistakes, we build on the best practices established in the space industry. Every space project at Creotech Instruments follows ECSS standards across all four branches (Management, Product Assurance, Engineering and Sustainability). We successfully passed ISO 9001:2015 certification in the Design and Manufacture of Electronic Devices, and Earth Observation Services. All our flight hardware is assembled on site in a dedicated ISO 7 (Class 10,000) cleanroom.

26 projects with TLR of 7+

16 years of innovation on the market

14 space Missions including 4 for ESA

110 scientists, engineers and doers on board

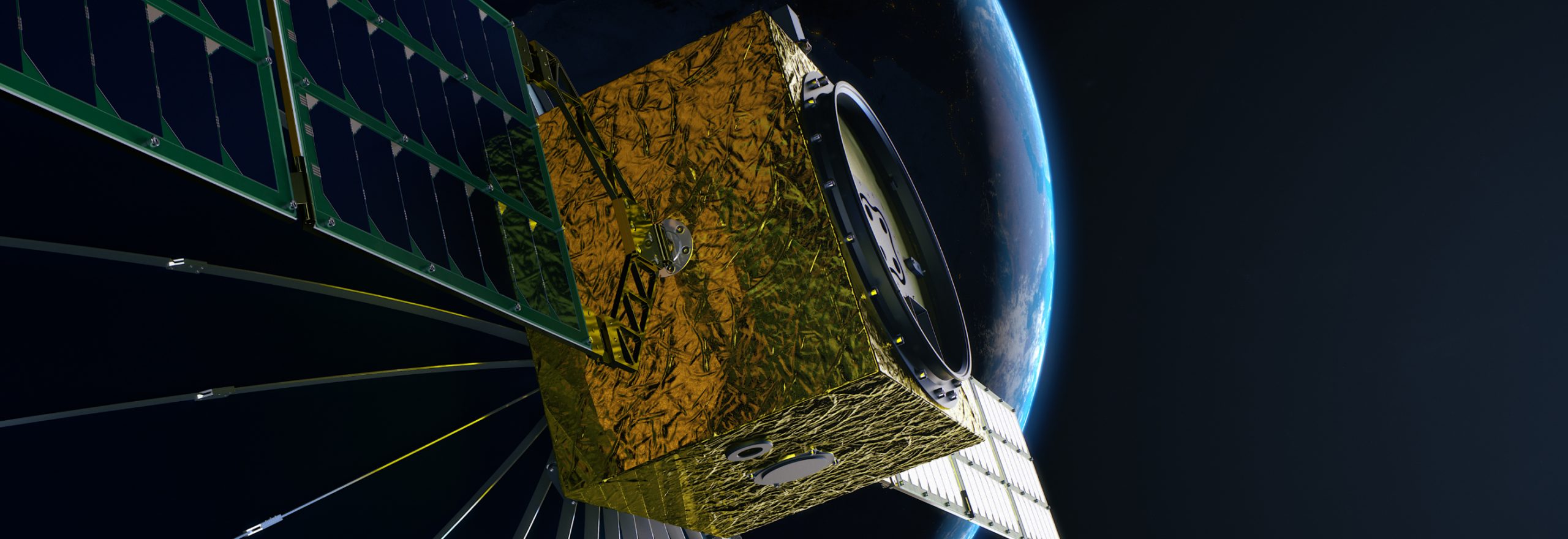

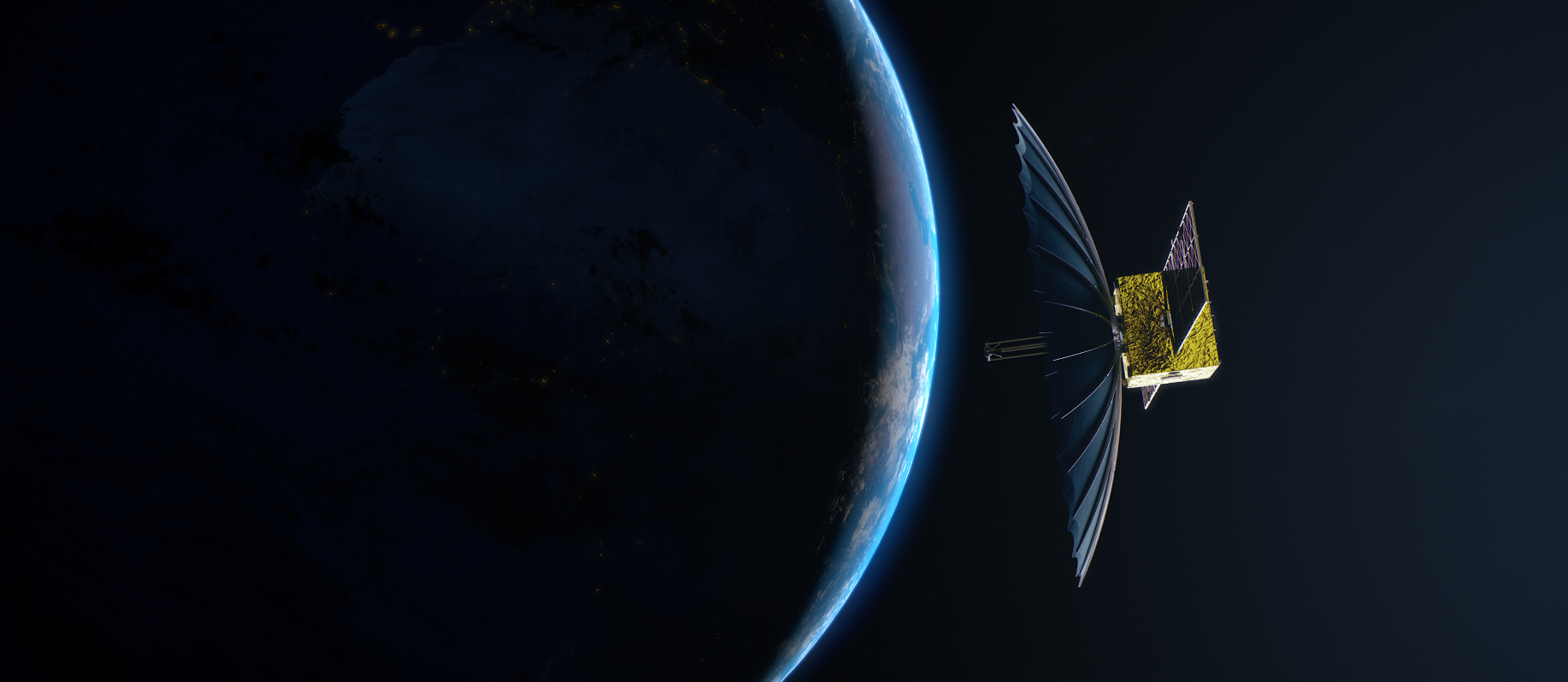

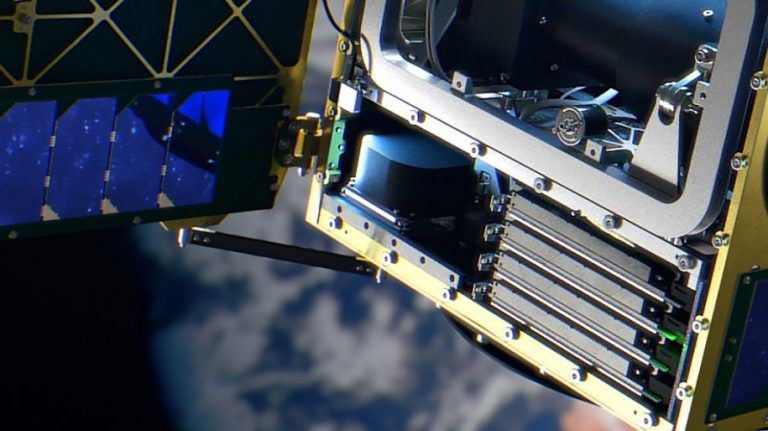

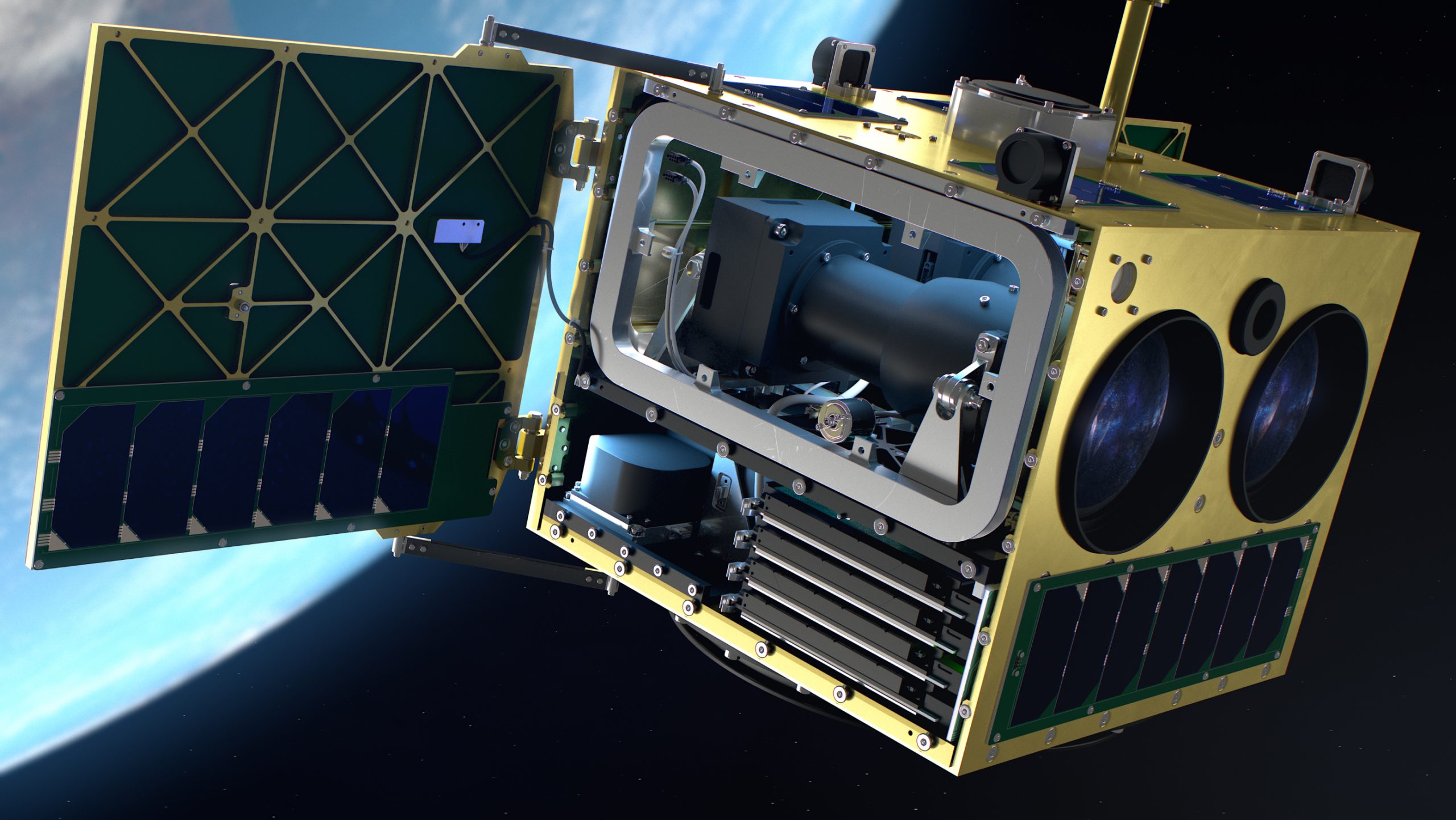

HyperSat

HyperSat - our own built - modular, universal satellite platform, that equipped with specialized instruments, will allow you to carry out a wide range of space missions, for various purposes. The culmination of many years of Creotech’s Instruments experience.

Rapid Implementation

Thanks to the use of the HyperSat platform, new microsatellites and constellations will be noticeably less expensive, vastly faster to implement, easier to operate and, thanks to the standardised model, a lot more reliable.

Space at arm’s length

Creotech Instruments, by developing the HyperSat project, optimises the satellite industry by aiding traditional space companies as well as entities working in the New Space field. Our platform will vastly ease the market entry to new companies.

CUBESAT modular elasticity

HyperSat is based on the best practices developed in the creation of pico- and nanosatellites (CubeSat) that weigh no more than a few kilograms. It has, however, been developed with carrying instruments and equipment of larger dimensions in mind.

Proof of our experience and knowledge are the space missions we take part in:

-

The EXOMARS mission - searching for life on Mars

-

The ASIM project - the first space contract for ESA

As part of the global effort to hunt out risky celestial objects such as asteroids and comets, ESA is developing an automated telescope for nightly sky surveys.

Read more -

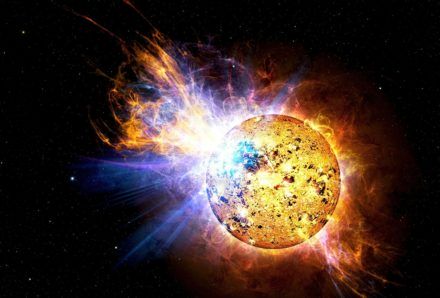

PROBA-3 will make research of the Sun's corona possible

As part of the global effort to hunt out risky celestial objects such as asteroids and comets, ESA is developing an automated telescope for nightly sky surveys.

Read more -

SAT-AIS-PL - the first Polish industrial satellite

-

Earth's early warning system NEOSTEL

As part of the global effort to hunt out risky celestial objects such as asteroids and comets, ESA is developing an automated telescope for nightly sky surveys.

Read more

Products & Services

We offer a wide variety of satellite platforms and subsystems at various Technology Readiness Levels (TRLs). Please contact us to discuss options.

Platforms

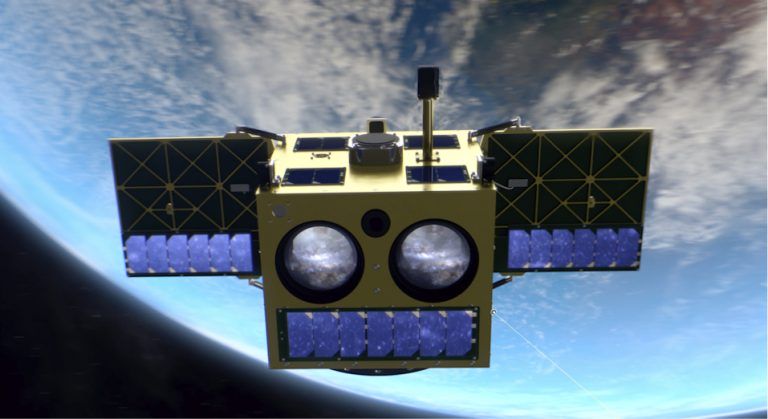

Thanks to its modularity, the Hypersat platform scales with your mission needs. New subsystems can be easily added thanks to the use of SpaceVPX standard with a backplane supporting 3U and 6U formats. Hypersat is based on COTS components and is free of ITAR restrictions.

Nanosatellite bus, intended for use in constellations, capable of orbiting in close formation. Compatible with CubeSat instruments. Features a dedicated monopropellant (HTP) propulsion system. Power: 20 W (orbit average power), communication: 1Mbps S-band, spacecraft pointing accuracy: 30”, size: 10 cm x 40cm x 40 cm, mass: 10kg. Current TRL: 4 (functional verification)

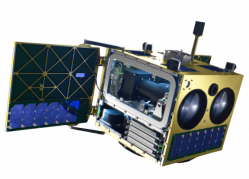

Microsatellite bus, intended for use in constellations or as a single satellite. Optimized for commercial and scientific missions, e.g. as a stable platform for space telescopes. Power: 35W (orbit average power), communication links: 1Mbps S-band and 50Mbps (downlink) X-band, spacecraft pointing accuracy: 30”, size: 30 cm x 40 cm x 40 cm, mass: 40 kg. Current TRL: 6 (technology demonstration in relevant environment)

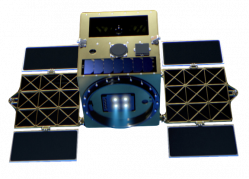

Microsatellite bus, intended for use in constellations or as a single satellite. Optimized for Earth Observation missions, both at LEO and VLEO. It can be equipped with a selection of chemical and electric propulsion systems, including a dedicated HTP engine. Power: 65 W (orbit average power), communication links: 1Mbps S-band or 50Mbps X-band, spacecraft pointing accuracy: 30”, size: 50 cm x 40 cm x 40 cm, mass: 60 kg. Current TRL: 5 (reduced-scale verification in relevant environment)

Subsystems

We offer a wide variety of subsystems, at various Technology Readiness Levels (TRLs), which can be customized to fit with your satellite architecture.

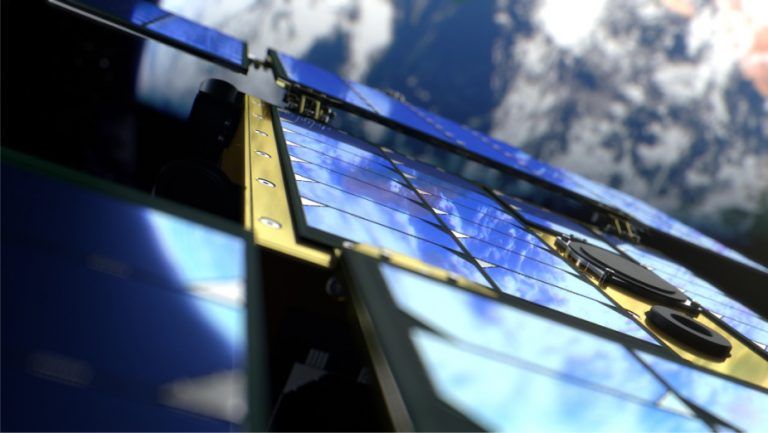

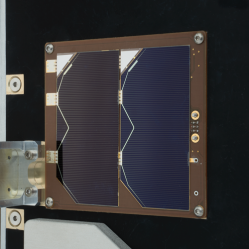

We offer design and manufacturing services for custom solar panels with the following features: structure mounted or deployable, high efficiency triple junction cells, up to 80W per panel, reverse bias protection, configurable cells connection – multiple cells in series or parallel, high radiation resistance, atomic oxygen resistance, temperature sensor can be added on demand. Current TRL: 6 (full-scale demonstration in relevant environment)

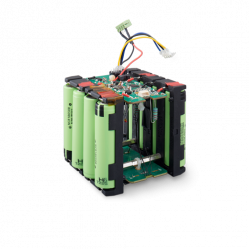

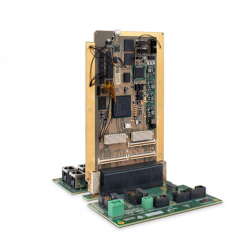

We offer a scalable battery management module with the following features: 80Wh capacity with 8S1P configuration; 3-5 year lifetime depending on depth of discharge and battery cycles; included battery charge controller and balancer; overcurrent, overvoltage, undervoltage, under discharge protection; RS-485 interface; unregulated 28V nominal voltage; stackable battery packs. Current TRL: 6 (full-scale demonstration in relevant environment). The picture shows a prototype.

We offer a scalable electrical power subsystem with the following features: configurable number of MPPT modules, capable of operating with our solar panels, power conditioning and distribution unit in the form of SpaceVPX module, single strain or fully redundant system, up to 200W power throughput, unregulated 28V, regulated 12V and 3.3V outputs, included LCL protection, compatibility with electric propulsion systems. Current TRL: 6 (full-scale demonstration in relevant environment)

We offer design and manufacturing services for thermal control systems: we assist to select best TCS solutions: heat pipes, heaters, radiators, experience with several coating solutions: paint, anodizing, MLI, assistance in thermal vacuum testing,. Current TRL: 6 (full-scale demonstration in relevant environment)

We offer full support in design and assembly of Multi-Layer Insulation for space missions: up to 16 grounded layers, assembly with adhesives, velcro attachment to the spacecraft. Current TRL: 9 (flight proven)

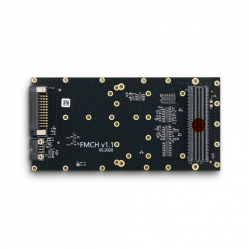

We offer an onboard computer subsystem with the following features: spaceVPX 3U form factor, multiple SpaceWire interfaces, ARM microcontroller with 100Mhz clock, 128MB operational memory, 64GB for data storage, 8MB non-volatile FeRAM memory for application image, software port of RTEMS operating system with board support package and drivers, current. TRL: 6 (full-scale demonstration in relevant environment)

We offer a CCSDS engine with the following features: spaceVPX 3U form factor; spaceWire, LVDS, RS485 interfaces for communication with bus and radio modules; fully compliant with CCSDS communication standard; data encryption and authentication; up to 50Mbit throughput. Current TRL: 9 (flight proven)

We offer full support in the design and manufacture of spacecraft harnesses for space missions: support in harness design for fully space qualified or COTS based projects; harness design for high power/ high throughput/ low level signals (shielded). Custom harness configuration possible, experience with internal/external harness (atomic oxygen resistance etc.), compliance with industry standards (ESA/NASA/custom tailoring). Current TRL: 6 (full-scale demonstration in relevant environment)

For each our subsystem we offer an electrical ground support equipment for testing and integration. We can also provide EGSE for custom subsystems with following capabilities: EGSE testers/ subsystem simulators; spaceWire, LVDS, RS422/485, UART, I2C, CANbus and custom interfaces possible; analog signals (sensors, power, load simulators); flexible architecture based on our Sinara products; python API. Current TRL: 8 (flight qualified)

Manufacture & Integration Services

We regularly manufacture and integrate components and subsystems for a wide variety of clients. This includes both engineering models and final flight models.

Various electronic subsystems produced at Creotech Instruments have already been successfully flight-validated. TRL: 9 (flight proven)

We can manufacture main and/or auxiliary harnesses to ESA standards. Several harnesses produced at Creotech Instruments have already been successfully flight-validated. TRL: 9 (flight proven)

We offer assembly & integration services for satellite missions in a dedicated ISO 7 (Class 10,000) cleanroom, equipped to enable assembly and testing of individual elements of space electronics, as well as integration of satellites weighing up to 150 kg.

Delivering solutions to the most demanding sectors and Partners

Subscribe to receive latest news:

Subscribe to receive latest news: