Contract manufacturing

Manufacturing

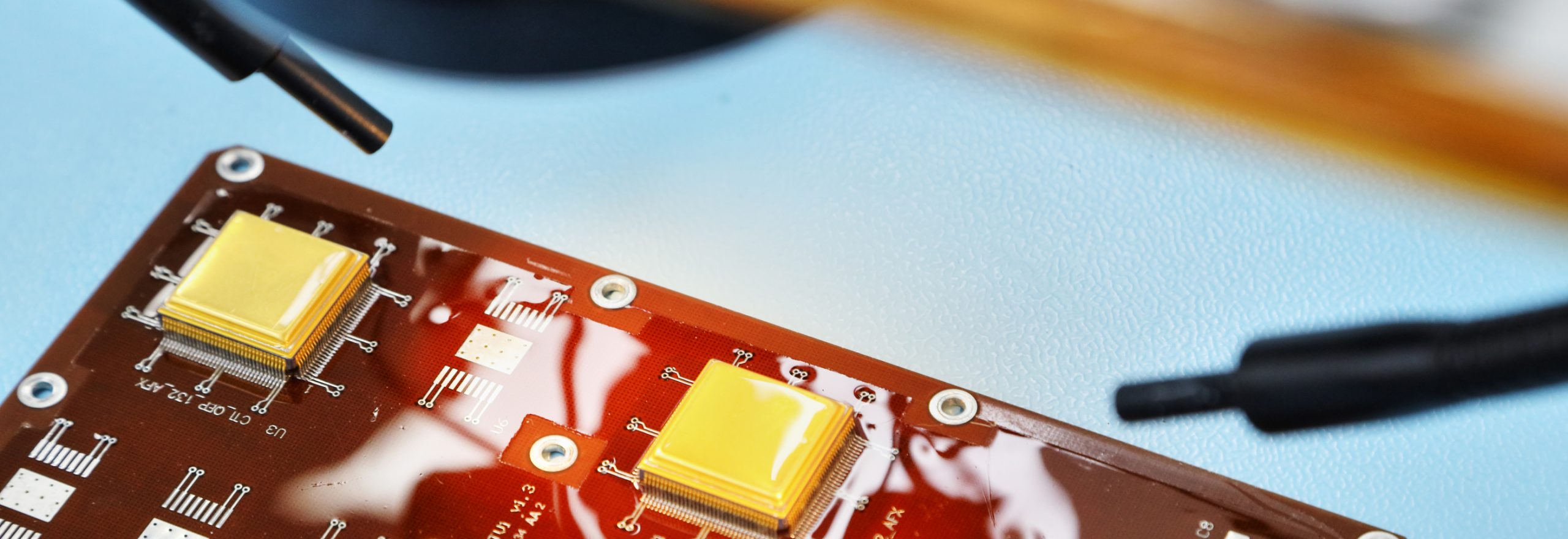

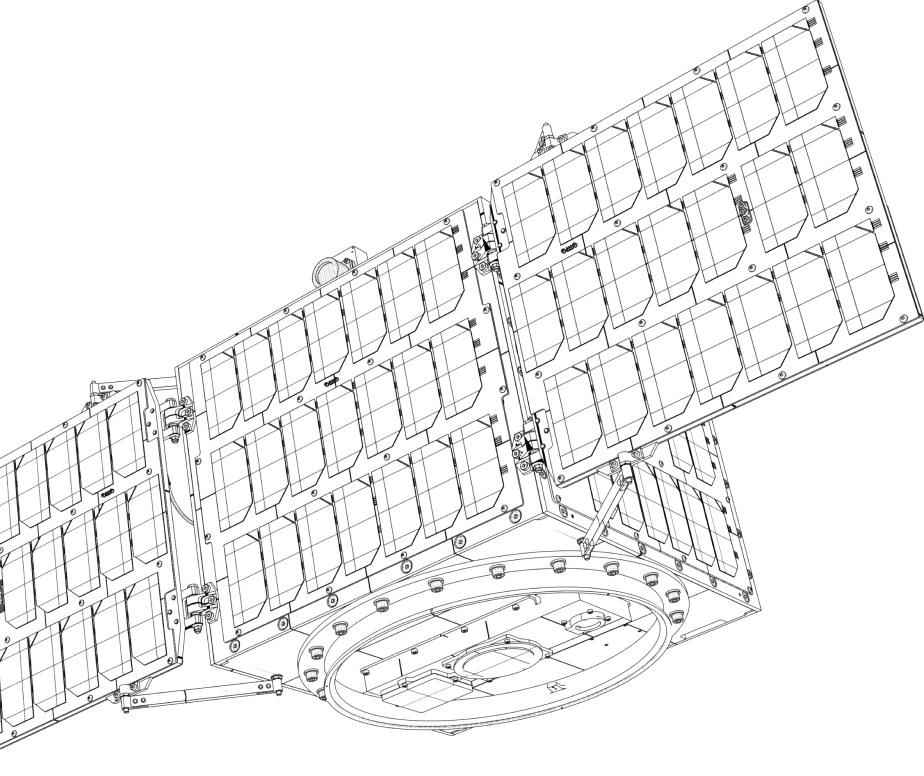

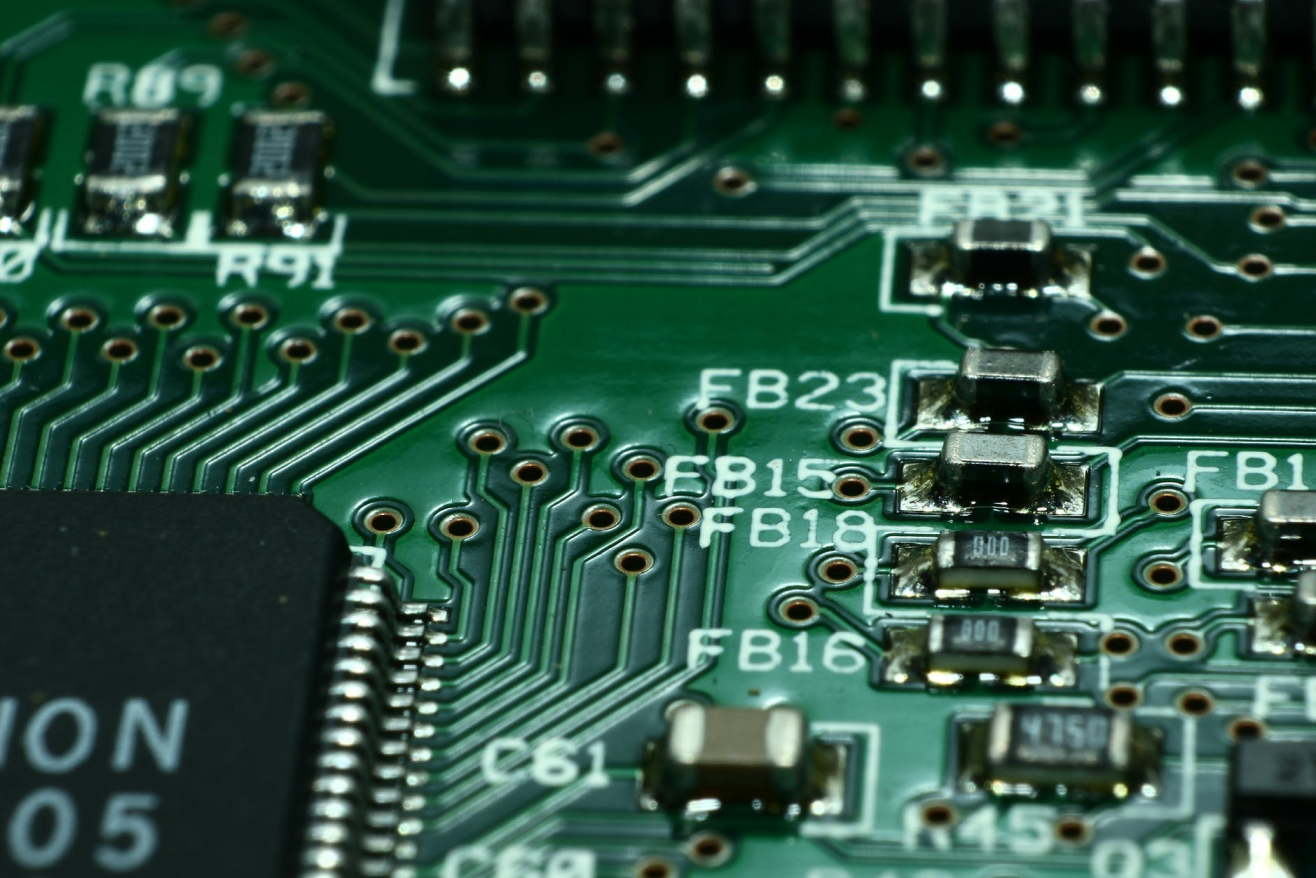

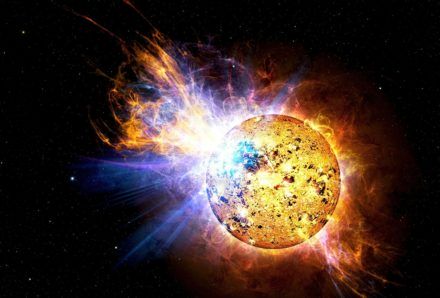

We provide comprehensive services of assembly of electronic devices to clients that require the highest quality and reliability, such as the space, the automotive, or the medical industries. We are the only Polish provider of contractual services of electronic assembly holding certificates from the European Space Agency. Devices produced by Creotech Instruments S. A. are used throughout the world and in space, in orbits of both Earth and Mars.

Full assembly for production (PCB, components, blueprints)

SMT and THT assembly in both lead and lead-free technologies

Vacuum soldering

Automatic optical and Xray inspection

PCB cleaning

Selective application of protective coatings

Final assembly

Press Fit assembly

Technical consulting and testing

Full traceability of individual devices from a batch

Production of cable harnesses

Climatic research

Production facilities

Within its production area, Creotech Instruments has clean rooms with ISO 8 and ISO 7 cleanliness classes, with the possibility of achieving ISO 6. Their total area is approximately 200 m². All surfaces are protected against electrostatic discharge (ESD) and humidity controlled.

Capabilities & Equipment

We have a machine park that allows the assembly of the most complex electronic devices in lead and lead-free technologies.

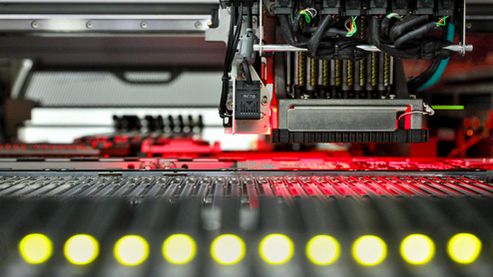

Surface Mount Technology (SMT)

- Automatic Juki Line:

- Stencil Printer,

- 2x Pick&Place Machine(17000cph and 29000cph),

Convection Reflow Oven

- Components size from 01005 to 74mm square or 50×150mm

- Component types: BGA, CCGA, CSP, QFN, QFP and many other

- PCB size: from 50x50mm to 810x360mm

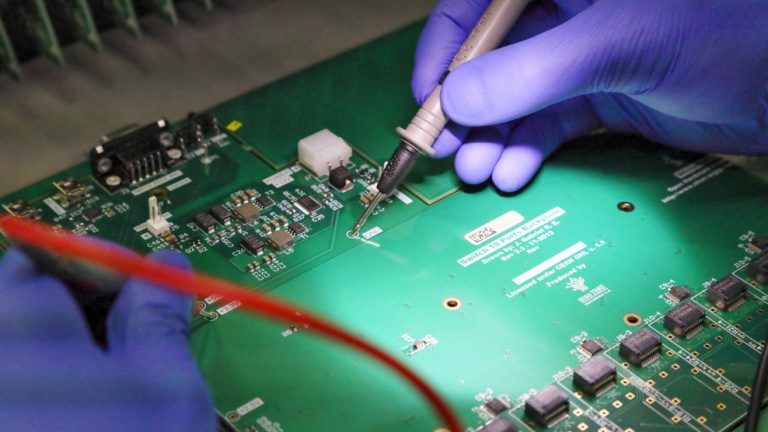

Inspection

- AOI MEK PowerSpector

- Inspectors with ESA certificates

- Through Hole Technology(THT):

- Selective Soldering Machine(ERSA)

- 7 fully equipped manual soldering nests

Other

- Rework, Cleaning, Conformal Coating, Press-Fit, Electrical Tests

- Climate chamber testing – Binder MKFT 240(-70⁰C – 180⁰C)

- X-ray, cross-sections – outsourcing

- Component lead forming – Fancort equipement

High quality is our standard

Creotech Instruments S.A. offers contract electronic manufacturing services delivered to strictest standards. We are committed to consistently delivering top-quality reliable products. Thanks to our highly qualified employees and the experience gained by manufacturing hardware used in the unforgiving conditions of space, we are in a position to tackle even the most challenging and ambitious projects.

To meet these expectations, we must consistently expand and improve our market knowledge and technological expertise in every facet of our activity. Our engineers and specialists are holders of ESA certificates: ECSS and IPC. We use top-of-the-line Juki assembly machines and can assemble 01005, CSP, QFN and BGA components. We offer a wide variety of services, such as SMT and THT prototype and serial production, assembly of elements, start-up and functionality testing. We provide technical assistance every step of the way.

Some of our recent projects

Delivering solutions to the most demanding sectors and Partners

Downloadables

Meet Creotech

Culture of forward-thinking, delivering solutions and always pushing bounderies brought us here.

Subscribe to receive latest news:

Subscribe to receive latest news: